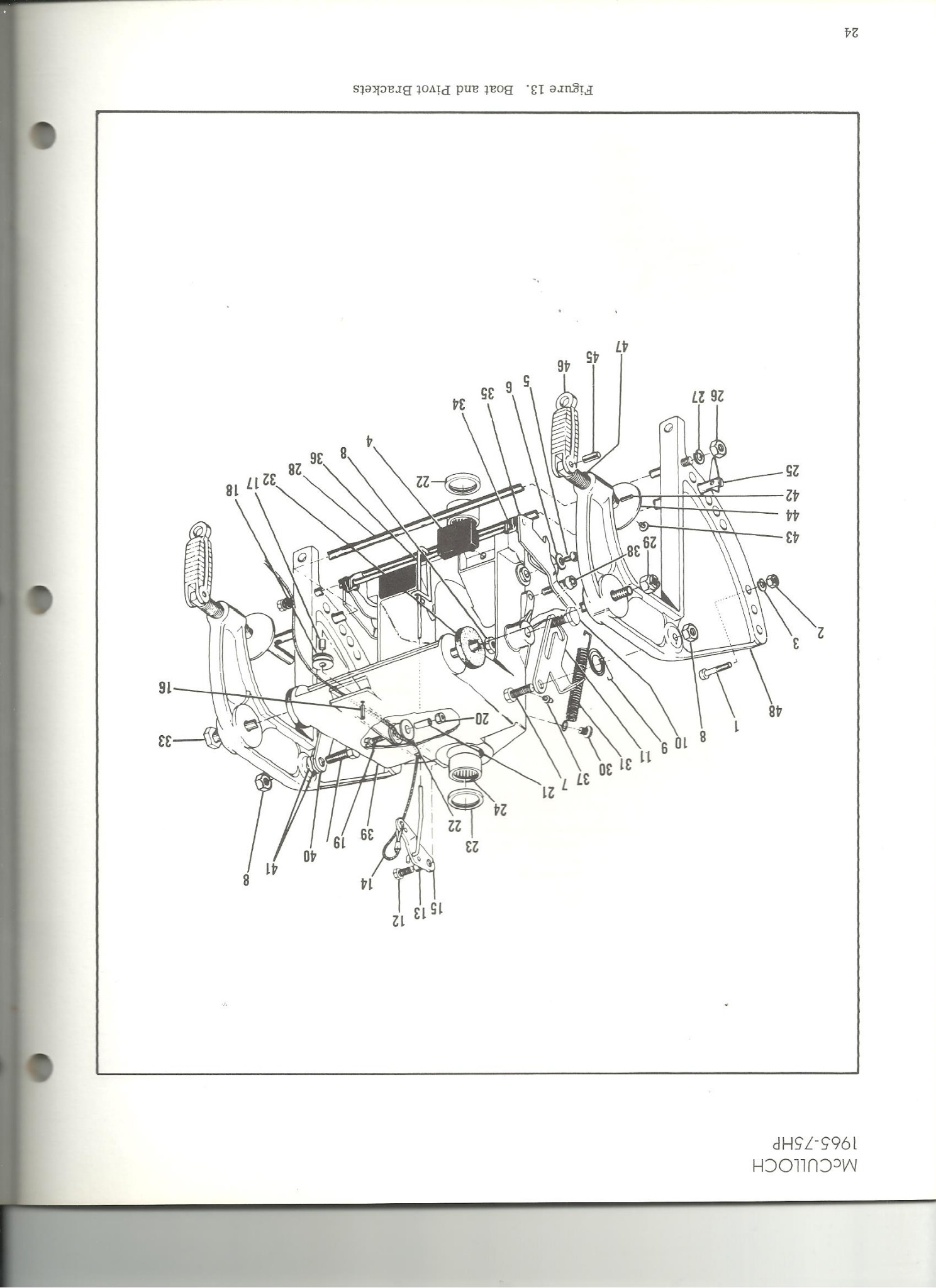

I have one on my 1965 75hp/65 Lone Star Mustang. I have attached a scan of the motor-end of the setup. Here is how I had to figure mine out... there was a short length of snapped, bare cable exiting the motor in the area where the steering cable attaches - that snapped cable was still around the pully (#18 in the drawing) and headed to the starboard side transom at the gunwale. The dashboard had a t handle which could pull the core strand of the cable, against the cable's fixed outer sleeve (Imagine a bicycle brake cable). That entire cable ran down the starboard gunwale, and after taking a turn at the transom, the cable end was fixed in a clamp to keep the sheath fixed. The inside core cable then continued on where it was spliced to that spanned bit of cable I described earlier (#14 in the scan, coming around the roller #18 in the scan and headed to starboard corner of the transom.

Having taken a MASSIVE retoration of the boat and the motor, I haven't ever gotten this thing to run right, but here is something to try. If you have a snapped bit of cable at the motor, pull on it. You will feel spring tension, and then something like a latch releasing. Meanwhile, have someone lift the lower unit upwards away from the keel until they hear anther latch, let go of the cable, and then let the motor's "leg" back down. You will notice that the motor's leg iis now much higher up (shallow drive).

If you pull the cable again, the motor literally FALLS back to standard position. In operation, you have the motor in idle in neutral, you pull the cable, and shift into reverse with lowest possible rpm. The motor lifts itself into shallow drive, and you let up the tention on the t-handle, or snapped bit of cable. The whole thing is a bit violent in action, especially when the motor kicks itself up, and then clunks back down when you want it back in standard so be prepared!