|

Welcome,

Guest

|

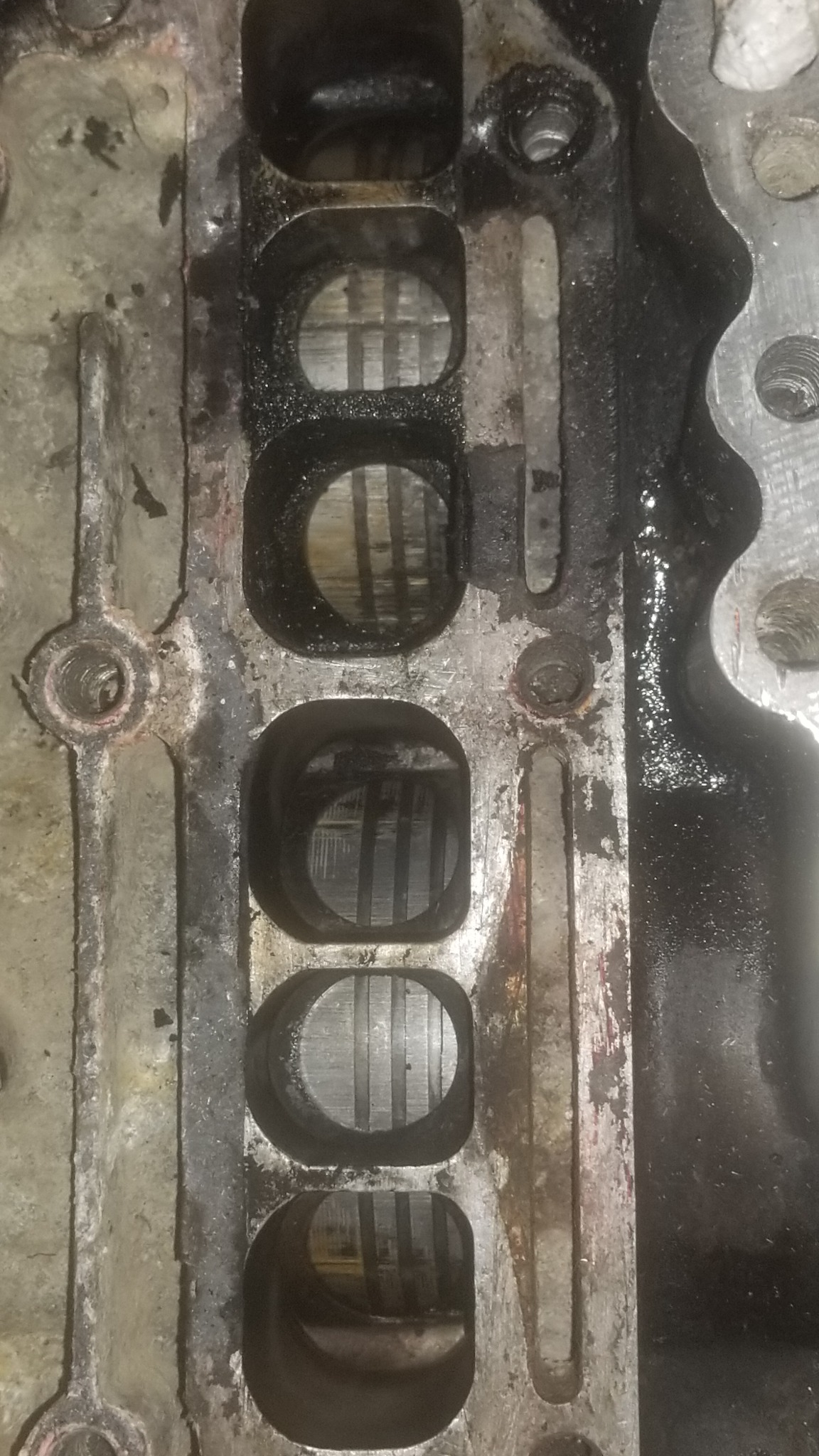

TOPIC: moisture in number 2 cylinder.

moisture in number 2 cylinder. 1 year 9 months ago #148024

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 1 year 9 months ago #148025

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 1 year 9 months ago #148029

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 1 year 9 months ago #148031

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 1 year 9 months ago #148032

|

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 1 year 9 months ago #148140

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 1 year 9 months ago #148141

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 1 year 9 months ago #148144

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 1 year 9 months ago #148145

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 1 year 9 months ago #148149

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 1 year 9 months ago #148150

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 11 months 4 weeks ago #148754

|

Please Log in or Create an account to join the conversation. |

moisture in number 2 cylinder. 11 months 3 weeks ago #148760

|

Please Log in or Create an account to join the conversation. |