OK, so that explains the temps. But the difference in temps is indicative of whatever issue it's having. So #1 isn't having as good of combustion as #2 or is making less power. Maybe because of the difference in spark timing? IDK but you're gonna have to correct that before pressing on.

Most outboards are probably gonna be happy at 0-to-5 deg BTDC at idle. Each one is particular about where it wants to run at.

So whatever yours is when you're getting a "happy" idle out of it. There is usually a synchronization mark on the throttle linkage, such that timing is advanced so many degrees and then the carb will start to open. Typically you'd want the carb butterfly fully shut or whatever small opening is necessary to get it idling well, before timing kicks in.

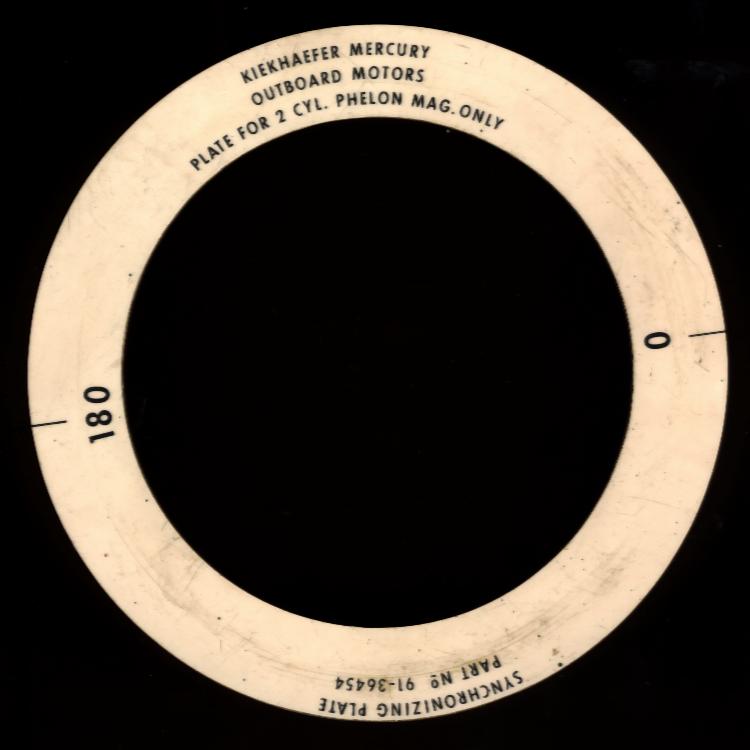

At any rate, you need to set up the degree wheel for #1 set of points opening, then adjust the gap on the 2nd set of points so that it opens exactly 180 deg after the 1st set. Then adjust the maximum spark advance stop based on points set #1.

Then you should have consistent timing between the 2 cylinders and it should run better just as a consequence of that. You can use a test light to tell when the points open/close. A "Buzz Box" is ideal, but they are rather expensive.

Here's some good info on how you'd use a Buzz Box to set points, and handy instructions on a D-I-Y model:

dansmc.com/buzzbox.htm